Overview

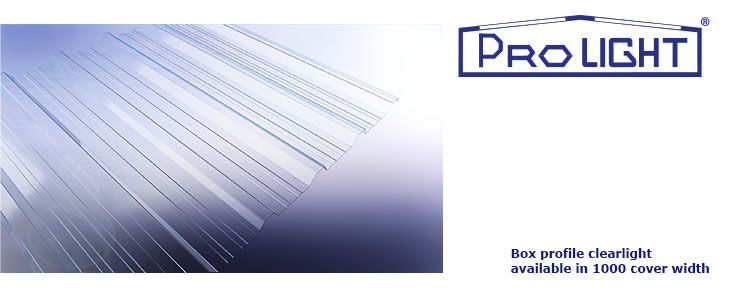

ProLight is a polycarbonate box profile clearlight designed to match our 1000/32 range of profiled sheeting.

Profile

Application

ProLight is a through fixed clearlight designed to match our 1000/32 range of profiled sheeting. It may be used in both roof and wall applications.

Available Lengths

Standard lengths available ex stock (m): 2, 3, 3.650, 5, 6.650 and 7.5.

Thickness

1.3 mm

UV Protection

ProLight includes a UV barrier on its top surface.

Chemical Resistance

There should be no aggressive environmental conditions or chemicals where ProLight is used. Contact with solvents and alkali cleaners should be avoided.

Condensation

Condensation may form on the underside of a roof made from any thin sheeting material. To minimise condensation within an enclosed structure, sources of moisture should be minimised and good ventilation should be provided.

Safety

ProLight® is a glazing material and should therefore be handled with due care at all times. Never walk on ProLight® sheets.

Isolation from plastisol coating

Plastisol coating on roofing sheets is aggressive to polycarbonate. It is essential that the lapped area of metal sheet at either side of and at the lower end of the ProLight has an aluminium foil adhesive tape applied to completely isolate the polycarbonate from the plastisol coated metal.

Purlin centres

Where purlin centres exceed 1800mm or are less than 1200mm guidance should be obtained from Duggan Profiles.

Fixing to treated timber

When fixing to treated timber purlins an EPDM barrier must be used to prevent any reaction between the treatment and the Prolight sheets.

Non fragility classification

Prolight satisfies the requirements of the Health & Safety Authority “Code of Practice for Safety in Roofwork” 2005 for Class B non-fragility subject to correct installation and maintenance. Full details are available from Duggan Profiles.

Quality & Durability

ProLight sheets are manufactured from the highest quality materials, using state of the art production equipment to rigorous quality control standards, complying with ISO9001 quality standard, ensuring long term reliability and service life.

Storage

Storage should be indoors as far as possible. Where Prolight is stored outdoors it must be protected from the sun, wind and water to prevent temperature build-up that could lead to distortion and degradation. Water between the sheets accentuates these processes.

Fixing Instructions