General Information

Tube Ties are an anti sag component which may be used in roof or wall situations. In physical terms they are identical to Tube Struts but act in tension rather than compression. They can be a more efficient anti sag component due to the significantly greater loadings that may be transferred. The Load data section provides further details.

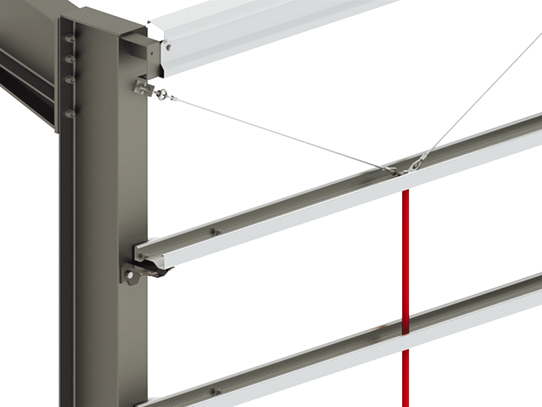

The range of possible applications is vast however the general principal involves anchoring the tie to the structure and suspending the load from this support (examples are shown above). Typical connection details are outlined in the Applications and Connection configurations section below. For recommendations on the appropriate use of Tube Ties and guidance on the selection of suitable anti sag systems in general please refer to Anti Sag Systems.

Types of Tube Ties

There are 3 distinct types which are distinguished by the type of end connection used.

DP-TS: This is the most commonly used type. It may be used with either ProSigma+ or Cee sections and with all section depths except the 145 deep ProSigma+.

DP-TS145: This is exclusively used for the 145 deep ProSigma+ in conjunction with the Tube Strut Spacer. The standard DP-TS will not fit this section due to the narrow central web. Refer to the Joint Detail for the DP-TS145 for further detail.

DP-TSFF: This is designed for use with counterformed Cee sections for the provision of a flush finish on the outer surface. It is illustrated in the section Tube Tie connection to counterformed members.

| Tube Tie for all sections except 145 ProSigma+ |

Tube Tie for 145 ProSigma+ | Flush fitting Tube Tie |

Tube Ties are a bespoke component made to suit conditions on site and as such are fabricated to whatever length is required. Attention is drawn to the “LENGTH” dimension for each type as indicated above. This is normally 2mm less than the cold-rolled centres however for the DP-TS145 this is increased to 12mm to accommodate the Tube Strut spacer. Tube Ties may be supplied in lengths up to 3m.

Applications and connection configurations:

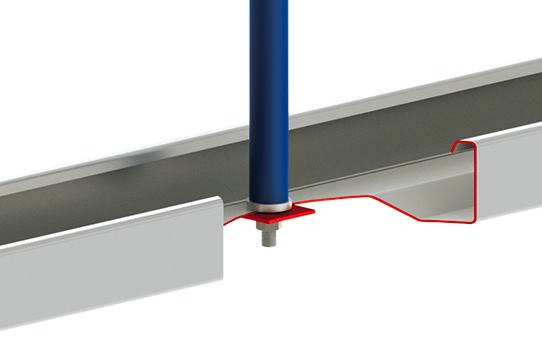

– Standard Tube Tie Joint Detail

The DP-TS is the most commonly used Tube Tie and it is shown in the diagram above. The male end of the Tie passes through a 14mm hole in the cold-rolled member and screws into the adjoining Tie.

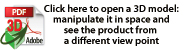

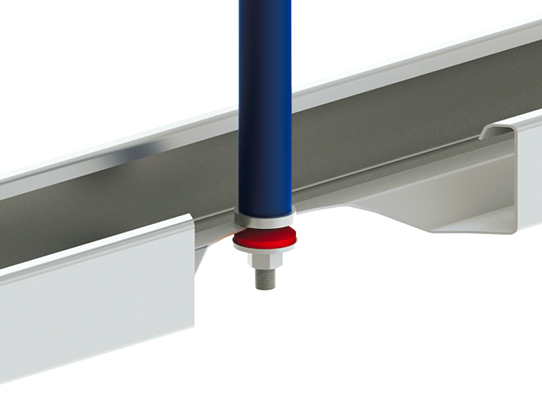

– Joint Detail for the DP-TS145 (used with the 145 deep ProSigma+ section only)

The DP-TS145 Tube Tie must be used with 145 ProSigma+ sections as the central web is too narrow to accommodate the width of the tube. The male spigot of the DP-TS145 is 10mm longer than the more commonly used DP-TS to accommodate the Tube Strut Spacer (shown in red in the image above). The profiled spacer fits in the narrow web of the section where the tie can’t access. Care should be taken to make allowance for the width of the spacer (10mm) when itemising lengths for order. Refer to the Product codes and drawings section for guidance in this regard.

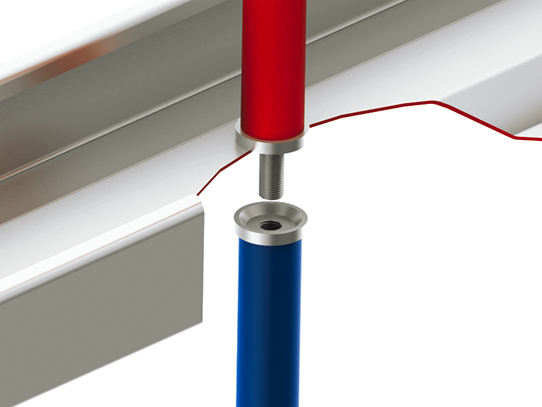

– Connection detail at bottom of run

Clamp Plates are used at the bottom of a run to help counter the effects of any concentration of load that might occur where Tube Ties are applied. An example is shown in red in the image above and one is recommended at the bottom end of every run. Clamp Plates cannot be used with the 145 ProSigma+ as the web is too narrow. The Connection detail at bottom of run (DP-TS145 only)outlines an appropriate detail for this case.

– Connection detail at bottom of run (DP-TS145 only)

Each run of Tube Ties for the 145 ProSigma+ section should be finished using a Tube Strut Spacer as Clamp Plates are too wide to fit in the web. A nut and washer secures the joint.

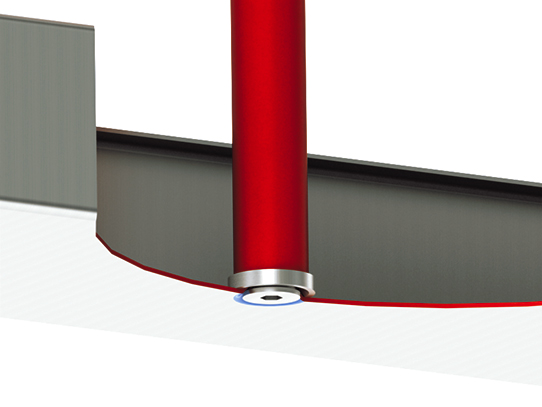

– Tube Tie connection to counterformed members

It may be desirable in certain circumstances to use Tube Ties with counterformed Cee sections. The image above illustrates such a case. The female end of any Tube Tie has a machined recess to allow it fit over a counterform. The “LENGTH” as indicated in the diagram above need not be amended. More details on the process of counterforming are available by referring to the Counterforming section of the ProSigma+ Customisation page.

Duggan Profiles Tube Ties have been tested to EN1993-1-3 to determine the load in tension that may safely be resisted. This is listed in the table below and is applicable to all types of Tube Tie. The value is constant irrespective of length and represents the maximum safe load these components can carry.

| Product Type | Tensile strength (kN) |

|---|---|

| DP-TS | 13.584 |

| DP-TS145 | 13.584 |

| DP-TSFF | 13.584 |

How to order

The code for each product along with a drawing are included in the table below. Clamp Plates and Tube Strut Spacers must be ordered if required as these are not supplied automatically.

ProSigma+ Tube Tie product codes and drawings:

| Code: | Description: | Length | PDF File |

|---|---|---|---|

| DP-TS | Tube Tie used with SIGMA+ 175 – 325 and all Cee Sections. Male/Female Ends | Cold-rolled centres – 2mm | |

| DP-TS145 | Tube Tie used with SIGMA+ 145 sections only. Male/Female Ends. 1 Tube Strut Spacer required per tie. | Cold-rolled centres – 12mm | |

| DP-TSFF | Tube Tie used where flush finish ends are required. Used with counterformed Cee sections. Female/Female Ends | Cold-rolled centres – 2mm |