STRUCAD SUPPORT

Detailing Support for StruCad Users

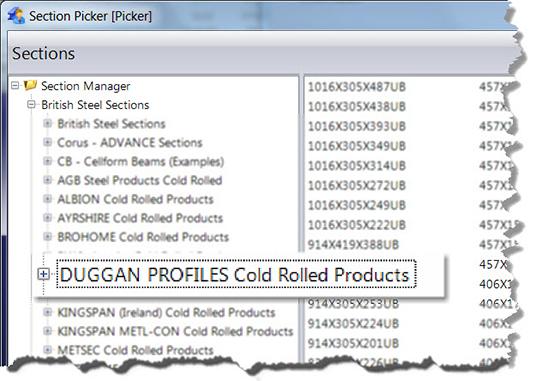

The Duggan Prosigma system is fully intgrated in StruCad. The complete range of Duggan Cold rolled sections is available for detailing from the sections catalogue as shown.

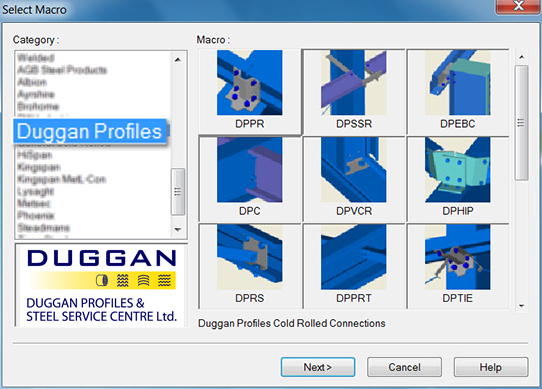

Duggan Connection Macros

In common with the systems of other manufacturers the Duggan Prosigma installation includes a suite of connection macros which may be accessed as shown below.

Purlin/Rail to Column/Rafter

This creates a cleat connection for both the Sigma and Cee sections. The following options are available:

- Prepainted or Galv sections may be used

- The type of Cleat may be defined

- Sleeves may be used

- Rafter Stays may be used

- Firewall slots may be used

- Orientation holes may be added

Simply supported rail to column

This creates a cleat connection for both the Sigma and Cee sections where the members are inset between columns/rafters.

This creates a cleat connection for both the Sigma and Cee sections where the members are inset between columns/rafters.

The following options are available:

- Prepainted or Galv sections may be used

- The type of hot rolled cleat may be defined (Duggan cleats are not suitable)

- Cleats may be slotted

- Members may be Notched around columns

- The inset distance may be varied

Eaves Beam to column

This creates an Eaves Beam cleat connection. The following options are available:

- Prepainted or Galv sections may be used

- Bolt-on or Weld-on cleats may be used

- The stock size may be defined

Note: Duggan Profiles do not supply Eaves Beam Cleats, these must be fabricated as part of the structural steel.

Connections for Cee Sections

This creates a connection between the following:

- Cee‘s and other Cee’s

- Cee’s and Eaves Beams

- Cee’s and columns/rafters

The following options are available:

- Prepainted or Galv sections may be used

- End Flanges may be used instead of cleats

- Hot rolled cleats may be used

- Notching may be used

Note: Use the Vertical Cladding Rail macro for connecting Cee’s to Sigma sections.

Vertical Cladding Rail connection

This creates all connections for the Vertical Cladding Rail (VCR). The following options are available:

- The horizontal rails may be any type of Sigma or Cee

- The VCR must be a Cee

- Cleat connections to columns may be defined

- Cover channels may be defined and used where required

- Tie Ropes may be used

Hip Connection

This creates a cleat connection between a Sigma or Cee and a hip rafter. The following options are available:

This creates a cleat connection between a Sigma or Cee and a hip rafter. The following options are available:

- The purlins may be any type of Sigma or Cee

- Weld-on or Bolt-on cleats may be used

Note: These cleats must be supplied by the fabricator.

Connection for Eaves Struts & Angle Struts

This creates the end connections for the Eaves Strut and the Angle Strut. These are standard connections and no adjustment is required however the following two connection options for the Eaves Strut are available:

- Eaves Strut connected to purlin web

- Eaves Strut connected to purlin flange

Purlin and Rail Tie connection

This creates the connections for Tube Struts, Tube Ties, Threaded Rod Ties and Apex Ties. It also makes provision for the inclusion of Tie Ropes. The following options are available:

- Sigma or Cee sections may be used

- Any Type of Tube Strut may be used

- Ties may be connected end to end or staggered (Anti sag requirements for Curved Roofs require staggered ties)

- Counterformed holes with countersunk bolts may be used

Connection for Tie Rope

This connects Tie Ropes with Tube Struts, Tube Ties, Angle Struts and Vertical Cladding Rails (VCR). The following options are available:

- Sigma or Cee sections may be used as the purlins or rails

- The anchor point at the column/rafter may be adjusted

- The anchor bracket at the column/rafter may be changed

- Tie Ropes can be inset for purlins/rails between rafters/columns

- Counterformed holes with countersunk bolts may be used

Cleader Angle Connection

This calculates the length of Cleader Angle required but does not create a connection. Duggan Profiles supply Cleader Angle in 6m lengths for screw fixing on site.

This calculates the length of Cleader Angle required but does not create a connection. Duggan Profiles supply Cleader Angle in 6m lengths for screw fixing on site.

Service Holes

This creates a Service Hole in Sigma sections 235 and deeper and all Cee sections. There are no user defined parameters for this macro and the hole must be applied on the centreline of the section.

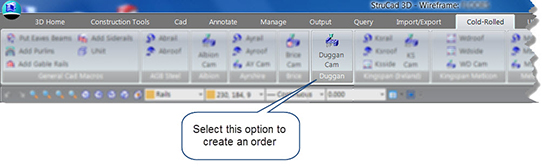

How to create an order:

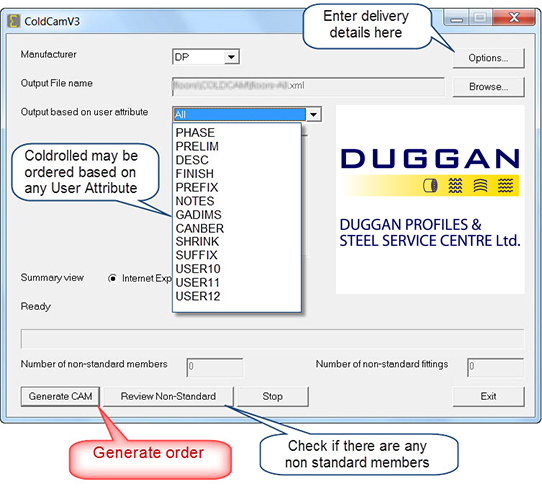

Cold rolled may be ordered from within the StruCad environment by selecting the “Duggan Cam” option on the cold rolled menu.

The dialog box below appears. The order may include everything in the model or may be broken down by Phase, Finish, Prefix etc., in fact Duggan Cam allows ordering of coldrolled based on any user attribute.

- Choose to order “All” or create the order based on one of the available user attributes.

- Check if there are any non standard items. Items may appear non standard for various reasons such holes not on expected gauge lines or items too long to make. If an item cannot be manufactured it must be edited before ordering. Drawings of non standard items should be included with the order.

- Enter delivery details.

- Click “Generate CAM”.

- Two files are created and saved to the folder you selected (Model directory/COLDCAM/ by default). These two files are “modelname”.asp and “modelname”.xml and they contain the list of non standard items and the order details respectively. Attach these 2 files to an email along with drawings of any non standard items and send them to your normal sales contact. Your order is now placed.