ANTI SAG SUPPORT FOR RAILS DURING CLADDING INSTALLATION

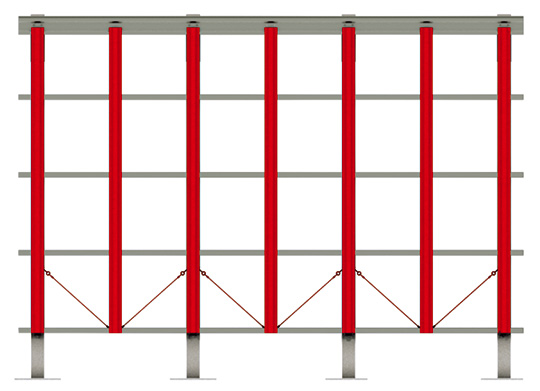

General configuration of anti sag members for cladding rails

The following guidelines are categorised by the distance spanned. They are for use with cladding which, when fixed restrains the side rail outer flange. It must be stressed that in any situation where general guidelines are presented there will be situations where these are either not applicable or require amendment. Some such cases are included in the section Additional considerations for specific cladding types. Care must also be observed on higher elevations or where heavier cladding is used to avoid overloading the anti sag system. In these situations multiple sets of Tie Ropes may be required. Refer to the section Additional considerations for higher elevations and heavy wall cladding for guidance.

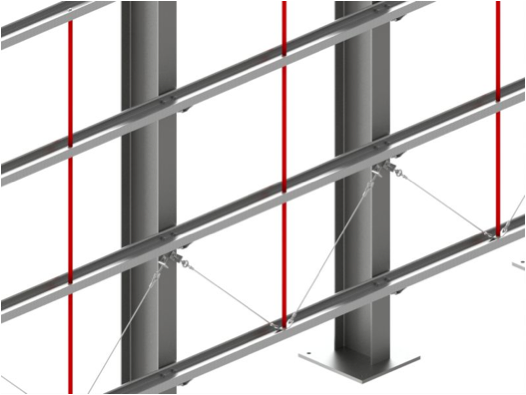

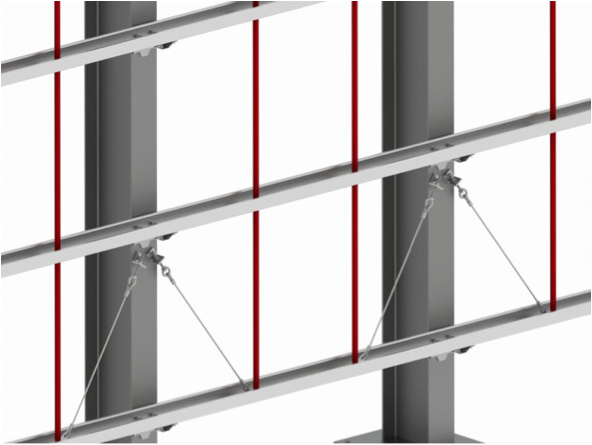

Construction details:

Span (M): 3 to 6.1m

Span (M): 3 to 6.1m

For spans up to and including 6.1m anti sag supports are recommended at: Mid Span

Components: Tube Struts and Tie ropes are used as shown.

Span (M): 6.1 – 9m

Span (M): 6.1 – 9m

For spans greater than 6.1m up to and including 9m anti sag supports are recommended at: 1/3 Points

Components: Tube Struts and Tie ropes are used as shown.

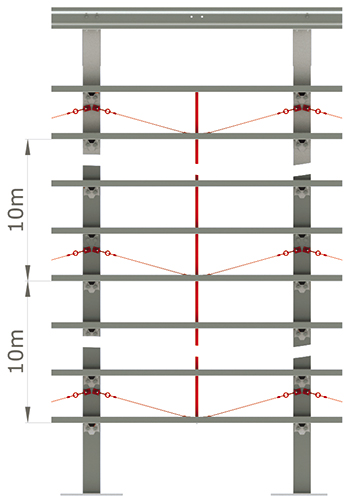

ADDITIONAL CONSIDERATIONS FOR HIGHER ELEVATIONS AND HEAVY WALL CLADDING.

On higher elevations the load on the anti sag system could be excessive. A similar situation could arise if an unusually heavy cladding material was used. In these situations additional anti sag members, in particular Tie Ropes are required. As a general guide a set of Tie Ropes is required every 10m as indicated in the diagram below.

Terms of use:

• The information contained above may be applied subject to the following restrictions and conditions. It is also advisable to seek guidance from Duggan Profiles as the information provided is of a general nature and inadequate to cover all possible scenarios.

• The guidelines apply where screw fixed steel sheeting is used which provides continuous restraint to the outer flange of the purlin.

• For sections greater than 265 Angle Struts should be used instead of Tube Struts.

• They may not be applied where non restraining cladding leaves the top flange under restrained. Refer to the section below for information specific to non restraining cladding.

ADDITIONAL CONSIDERATIONS FOR SPECIFIC CLADDING TYPES

Anti Sag Support for Non Restraining Wall Cladding:

The systems outlined above are for use with cladding which restrains the rail outer flange. If left unrestrained the rail is subject to the torsional effects due to side loading which should be avoided. When non restraining cladding is used the following conditions must be observed:

• Load tables for non restraining wall cladding must be used (Contact Technical Department).

• Angle Struts replace Tube Struts as the anti sag member used.

Further detail on these conditions is outlined below.

Load Tables for non restraining wall cladding

The standard Load Tables assume the top flange is fully restrained and may not be used where non restraining cladding is involved. A separate set of tables is available for this situation. These make allowance for the unrestrained nature of the flange. Please contact Duggan Profiles for appropriate loadings.

Anti sag support requirements for non restraining wall cladding

When non restraining cladding is used the anti sag components form an integral part of the structure post installation as well as resisting deflection during sheeting. Angle Struts must be used as Tube Struts do not provide adequate support to the compression flange and must therefore not be used. Information on the frequency of use of anti sag components is included in the Load Tables and should be referred to at design stage.

ANTI SAG SUPPORT FOR HORIZONTALLY LAID CLADDING:

Vertical supports of various forms are used to hold horizontally laid cladding. The weight of these should be factored into the assessment of Tie Rope requirements as they significantly increase the load on the side rails.

Vertical supports for horizontally laid cladding:

Tie Ropes may be used as normal with vertical supports such as Top Hats or Duggan VCR. The additional weight of these must be factored in when calculating the frequency of Tie Rope installation.