Additional considerations for:

– Anti sag support for higher elevation and heavy wall cladding

– Anti sag support for non restraining cladding

– Anti sag support for horizontally laid cladding

ANTI SAG SUPPORT FOR HIGHER ELEVATIONS AND HEAVY WALL CLADDING

On higher elevations the load on the anti sag system could be excessive. A similar situation could arise if an unusually heavy cladding material was used. In these situations additional anti sag members, in particular Tie Ropes are required. Use of the simplified guidelines presented above is not adequate and a more thorough assessment of the quantity and frequency of such components is required. The steps involved are as follows:

1. Determine the load per span – Tally the weight of cladding, rails etc.

2. Estimate the proportion of above supported by anti sag.

3. Check if the Tube Ties/Tube Struts can carry this load.

4. Check if the Tie Ropes can carry this load.

5. If the capacity is exceeded add additional sets of ropes as necessary.

Worked example:

How to determine a suitable anti sag arrangement for the following high elevation:

Span: 6m

Height of cladding: 10.5m

Rails DP-205/65/150 – weight 4.4 kg/lm

No. of rails: 8 at 1500 ctrs.

Weight of cladding: 15kg/sq. m

Weight of anti sag components: 1.5 kg/lm

Angle of incline of Tie Rope when fitted: 25°

Working limit of Tie Rope: 14.684kN

Working limit of Tube Tie: 13.584kN

Working limit of 1500 long Tube Strut: 3.402kN

5. Total load per span = Weight of cladding + Weight of rails + Weight of anti sag members = (10.5 x 6 x 15) + ( 8 x 6 x 4.4) + (10.5 x 1.5) = 1172kg

6. Assumption: It is assumed that approximately half the total load will be borne by the anti sag supports =>Load on anti sag system = 1172/2 = 586kg = 5.748KN

7. Working limit of Tube Tie = 13.584KN. This is adequate to support the load.

8. 2 ropes are used per span therefore the load per rope = 586/2 = 293kg. The rope is fitted in an inclined position and therefore the tension require to support a vertical load is increased = 293/ (Sine 25) = 693.3kg = 6.801KN. Compare this load to the capacity of the rope, 6.801< 14.684 therefore a single set is adequate for this situation.

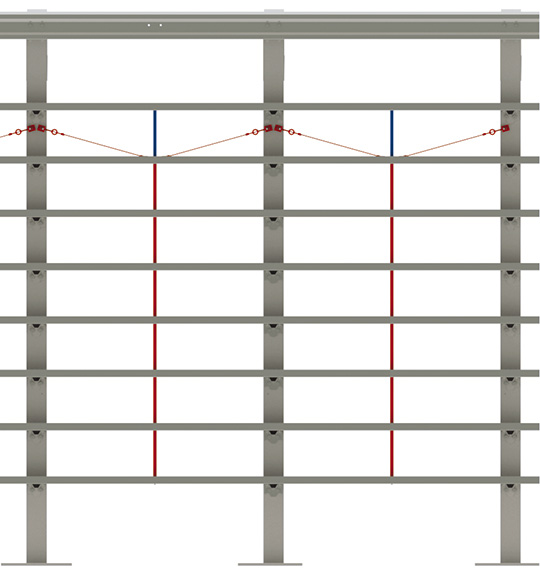

9. Tube Ties suspended from 2 Tie Ropes are adequate for this situation. The arrangement is shown in the diagram below.

Note: If Tube Struts were used the result is as follows:

1. Total load per span = Weight of cladding + Weight of rails + Weight of anti sag members = (10.5 x 6 x 15) + ( 8 x 6 x 4.4) + (10.5 x 1.5) = 1172kg

2. Assumption: It is assumed that approximately half the total load will be borne by the anti sag supports => Load on anti sag system = 1172/2 = 586kg = 5.748KN

3. Working limit of 1500 long Tube Strut: 3.402kN. This is not adequate to support the load.

4. 2 ropes are used per span therefore the load per rope = 586/2 = 293kg. The rope is fitted in an inclined position and therefore the tension require to support a vertical load is increased = 293/ (Sine 25) = 693.3kg = 6.801KN. Compare this load to the capacity of the rope, 6.801 < 14.684 therefore a single set is adequate for this situation.

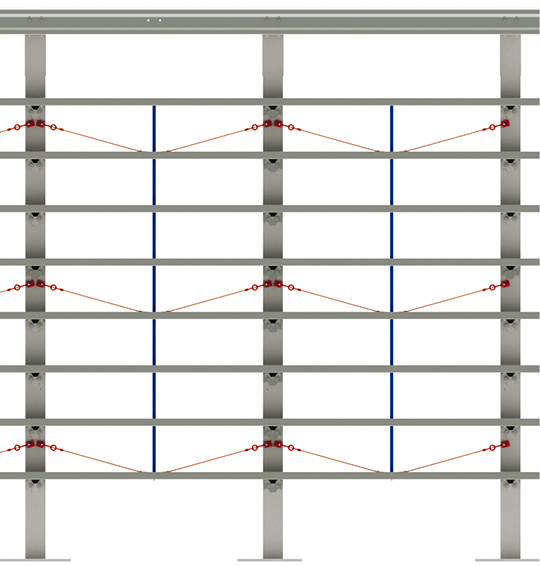

5. The Tube Struts can only accommodate 60% approximately of the required load and will therefore buckle. The solution is to addan additional set of Tie Ropes at approximately two thirds height but the purlin centres are such that 3 sets of ropes are required.

6. The arrangement is shown in the diagram below.

ANTI SAG SUPPORT FOR NON RESTRAINING CLADDING

The systems outlined in the sections Rails Anti sag support during cladding installation and Additional considerations for Anti sag support for higher elevations and heavy wall cladding are for use with cladding which restrains the rail outer flange. If left unrestrained the rail is subject to the torsional effects of side loading which should be avoided. Where the type of cladding or the method of fixing does not provide the restraint required Angle Struts may be needed instead of Tube Struts or Tube Ties. In addition to lateral support these also provide torsional support and can be more suitable in these situations. More specific guidance can be provided if the exact nature of the cladding type, weight etc. is known.

ANTI SAG SUPPORT FOR HORIZONTAL LAID CLADDING

Vertical supports of various forms are used to hold horizontally laid cladding. The weight of these should be factored into the assessment of Tie Rope requirements as they significantly increase the load on the side rails. The assessment method outlined in the section Additional considerations for higher elevations or heavy wall cladding can be used if checks are required.

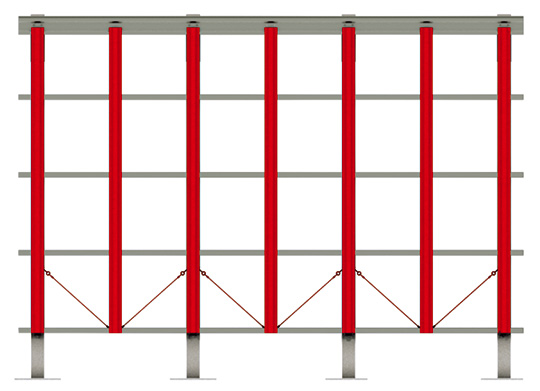

Vertical supports for horizontally laid cladding:

Tie Ropes may be used as normal with vertical supports such as Duggan Top Hat or Duggan VCR. The additional weight of these must be factored in when calculating the frequency of Tie Rope installation.