Duggan Profiles supply a range of cleats for our cold rolled sections. The various options are outlined below.

These are available in sizes to suit our range of Sigma+ and Cee cold rolled sections.Bolt on cleats are supplied primed as standard. Unprimed Bolt On Cleats can be supplied on special request and further details are available here.

These must be welded to the mainframe. They are available in sizes to suit our range of Sigma+ and Cee cold-rolled sections. Weld on cleats are supplied unprimed.

Bolt on or Weld on Cleats may be fabricated with extended leg lengths where conditions demand. Extended leg cleats are not standard and are available on special order. Bolt-on versions may be supplied primed or unprimed while weld-on are unprimed.

Any type of cleat may have a stiffening rib added to increase cleat strength. Stiffened cleats are available on special order only. Bolt-on versions may be supplied primed or unprimed while weld-on are unprimed.

Unprimed bolt-on cleats are not a standard product and must be prepared to order. An extended lead time applies. Extended and stiffened versions of bolt on cleats are also available unprimed on special order.

General Information:

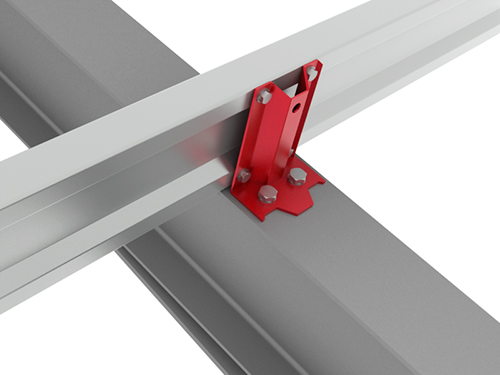

The cleats outlined above are used with both ProSigma+ and Cee cold-rolled sections. They are used irrespective of the finish of material (galvanised or prepainted) used for the cold-rolled. The joint arrangements for both are outlined in the diagrams underneath. M12 Grade 8.8 bolts are used for the 4 bolt connection to the section while for bolt-on cleats 2 M16 Grade 8.8 bolts secure the baseplate to the supporting steel structure. An additional 18mm hole is provided for the attachment of a safety harness connection. Manufacturing restrictions limit the maximum length of cleat available to 450mm, where cleats are required beyond this length such must be provided by the fabricator. Whereas the standard bolt on cleat is shown in the diagrams below similar arrangements equally apply in all cases.

Construction Details:

Cleat connection to purlin:

Cleat connection to Cee:

Standard Bolt-On Cleat:

Standard Weld-On Cleat:

Extended Leg Cleat:

Stiffened Cleat:

Load data:

The following results have been obtained:

|

Cleat Type:

|

Working load moment resistance (kNm): |

|---|---|

|

Unstiffened Cleats

(Bolt-on, Weld-on, Extended Leg Bolt-on, Extended Leg Weld-on). |

0.41 |

|

Stiffened Cleats

(Bolt-on, Weld-on, Extended Leg Bolt-on, Extended Leg Weld-on). |

3.08 |

The most authoritative cleat selection method is by reference to the table above. For convenience a quick reference Cleat Selection Guide has also been prepared and is included below. Users should however note the conditions of use for same listed below.

Cleat Selection Guide:

| Section depth | Max Span (M) | Max slope using Unstiffened Cleat (°) | Max slope using Stiffened Cleat (°) |

|---|---|---|---|

| 145 | 5 | 25 | 30 |

| 175 | 6 | 18 | 30 |

| 205 | 7 | 13.5 | 30 |

| 235 | 8 | 10.5 | 30 |

| 265 | 9 | 8 | 30 |

| 300 | 10 | 6.5 | 30 |

| 325 | 12 | 5 | 25 |

Conditions of use:

The table above gives the maximum roof pitch on which the corresponding cleat type may be used. The following provisos apply:

Calculations based on maximum load of 1.5 kN/m2 factored load, maximum spacing 1.8m and spans as shown.

Example: An unstiffened cleat to suit the 175 cold-rolled section may be used up to 18° with a corresponding span not exceeding 6m.

Readings in table based on standard cleat length and not applicable to extended leg cleats.

How to order:

All cleats are uniquely specified by product code and these should be used when ordering.

The codes for each product are included along with drawings and CAD files on the relevant page.

If ordering extended leg cleats the length of the extended offset must also be provided (Refer to a drawing of a typical extended leg cleat to see the dimension this refers to. These are available in the Product Codes and drawings section of the Extended Leg Cleats page).