Product Overview

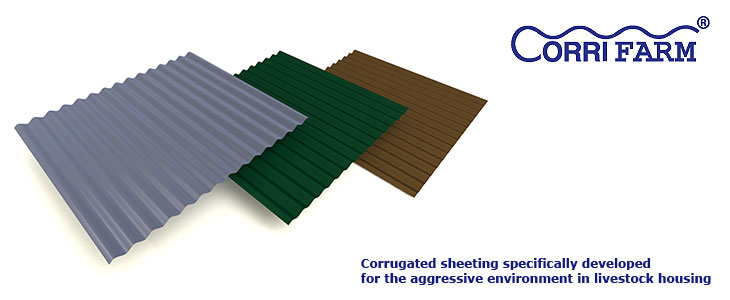

Sinusoidal profile sheeting available in two cover widths and specifically developed to cope with the corrosive environment experienced in livestock housing.

CorriFarm 10/3

CorriFarm 14/3

Applications

Roof and wall applications in livestock housing.

Lapping Configuration

Colours

| Slate Grey |  |

| Juniper Green | |

| Turf Brown |

Availability

Made to order in lengths 0.1 – 12 m or available ex stock as outlined below:

| Cover width | Colour | Thickness (mm) | Stocked lengths |

|---|---|---|---|

| 10/3 | Juniper Green | 0.55 | 1.829 m (6’) |

| Slate Grey | 2.134 m (7’) | ||

| 2.438 m (8’) | |||

| 2.743 m (9’) | |||

| 3.048 m (10’) | |||

| 3.353 m (11’) | |||

| 3.658 m (12’) |

Thickness

| Cover Width | 14/3 | 10/3 |

| Thickness (mm) | 0.55 | 0.55, 0.7 |

Material

Substrate: S220GD+Z275 to EN 10346:2009

Coating:

Underside: 35um Primer/Polyester

Weather side: 25um Primer/Polyester

Targeted Agriculture Modernisation Scheme (TAMS)

The Department of Agriculture has approved CorriFarm and ProFarm as products that meet the standards for roof and side cladding as documented in S102 on gov.ie

DPC Barrier

To prevent deterioration caused by contact with wet, green or treated timber a DPC barrier must separate Corrifarm when fixed to timber purlins.

Packing and delivery

All deliveries, unless indicated otherwise, are by road transport with packaging to suit land delivery. As a general guide pack sizes are limited to two tonnes and the entire pack is wrapped in polythene. Offloading is the responsibility of the client.

Storage & Handling

Water ingress between sheets will have a negative effect on the performance of the sheet. Wrapping is only a temporary protection for transport purposes and is not suitable for outdoor storage.

Quality

|

|

Overview

The complete range of Duggan Profiles sinusoidal sheeting can be curved or cocktailed subject to the manufacturing limitations that are described below. 0.7 mm material is recommended as it more easily retains the curved profile.

Available Lengths

The total length of curved or cocktailed sheets should be limited to 4.876 m (16′).

Requirements for manufacture of Curved Sheets

In order to curve sheeting the curved length and rise at mid span is required as indicated in the diagram below.

Stock

Curved ridges are available ex stock in 0.55 mm Corrifarm 14/3 & 10/3 Slate Grey & Juniper Green.

Requirements for manufacture of Cocktailed Sheets

Cocktailed sheets are made to order. The standard cocktail has a 6” rise over 18” cocktailed length. In order to manufacture the cocktail length and rise is required as indicated in the diagram below. Non standard cocktailed options are only available in limited cases due to the complexities of manufacture. Check that the required option can be produced before ordering.

Overview

NonDrip condensation control membrane is specially designed to help control condensation and prevent dripping in non-insulated metal buildings. It can be applied on our range of 14/3 corrugated or 1000/32 box profile sheeting.

Application

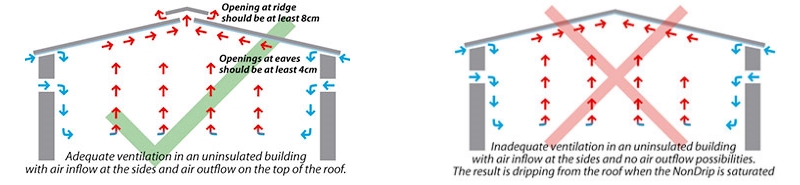

NonDrip membrane can help control condensation in an environment where the condensation appears cyclically. In order to work it needs to get dry in between cycles so it should not be used in buildings where relative humidity approaches saturation for extended periods. To facilitate drying adequate ventilation is necessary. Without proper ventilation the risk occurs of the build-up of moisture and droplet formation.

Installation

Care must be taken to avoid penetration of rainwater due to capillarity through the side or end laps. The following should be observed during installation:

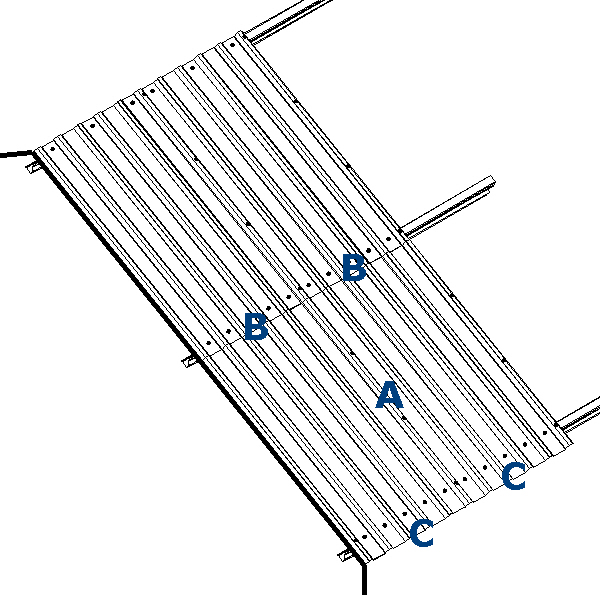

Vertical overlaps (A)

All profiled sheeting with NonDrip is supplied with the vertical side lap left uncovered. The capillary effects in the lateral direction (A) can be prevented by installing sheeting so the interior side is completely covered with NonDrip membrane (no bare metal visible).

End laps at (B) and (C)

Sheeting is supplied with the NonDrip membrane flame sealed (burn back) at one end. To avoid penetration of rainwater due to capillarity through horizontal overlaps B and C the following should be observed:

- The burn back should be at the downslope end of the sheet.

- The overhang of the eave above the gutter should be at least 15 cm to avoid rain water penetrating into the building. This part of the roof is permanently ventilated in the outside air.

Ventilation

Key to the working of NonDrip™ is sufficient ventilation within the building envelope, to allow it to dry. The air flow movement and temperature within the building structure, will determine how quickly the NonDrip™ membrane will return to its original dry state. The build up of condensation can be reduced in the first place by the use of natural ventilation provided by eave, ridge and wall openings.

Absorption capacity

The water absorbency rates listed below were found from laboratory testing. As the roof pitch increases the absorption decreases under the influence of gravity.

Absorption & Drying Properties

| Absorption at roof pitch | Unit | Value | Conditions |

|---|---|---|---|

| Absorption at 0 degree* | g/m² | 1037 | 100%RH, ΔT:17°C |

| Absorption at 10 degreeg/m² | g/m² | 716 | 100%RH, ΔT:17°C |

| Absorption at 30 degree | g/m² | 538 | 100%RH, ΔT:17°C |

| Absorption at 45 degree** | g/m² | 394 | 100%RH, ΔT:17°C |

| Drying speed*** | g/m²/h | 80 | 50%RH, 23°C |

*With the sheet laid flat, and the relative humidity within the building at 100%,and the temperature on the inside of the building 17°C higher than the outside temperature, 1037 g/m2 water was absorbed by NonDrip before it started to drip.

**This is an average time to drip for a roof pitch of 20 degrees given the relative humidity within the building at 100%, internal temperature of 40 degrees and the temperature on the inside of the building 17°C higher than the outside temperature. If the roof pitch is increased the time to drip will be somewhat shorter while lower angles will exceed 6 hours.

***With the relative humidity within the building at 50%, and the temperature on the inside of the building at 23°C, the drying speed was 80 g/m2/h.

Clearlights

Due to the risk of droplet formation on the underside of the light, clearlights are not recommended on a roof with NonDrip.

Purlins

All prepainted metal sheets, including those with NonDrip, should be separated from wet, green or treated timber purlins by a DPC strip.

Corrosion resistance

NonDrip™ does not negatively impact the corrosion resistance of the sheeting to which it is applied. The value of any guarantee supplied with sheeting will not be affected when NonDrip is used.

Chemical resistance

NonDrip should not be exposed to any solvents. Special care should be taken when using disinfectants. The disinfectant to be used should be tested on a small area to verify its effect. High pressures or hard brushes should not be used on the NonDrip membrane.

Installation precautions

To prevent damage to the NonDrip™ membrane, avoid rubbing the sheets together or against the roof structure.

Fitting Instructions

Click to Download the relevent Fitting Instructions

Corrifarm 14/3 Lap & Half Class B Non Fragility Installation Method (0.55mm)

Corrifarm 10/3 Lap & Half Class B Non Fragility Installation Method (0.55 & 0.70mm)

For Sales Post 1st January 2019 |

|||

1 |

Objective of the Guarantee |

||

| 1.1 | This guarantee (the “Guarantee”) applies to the sale and supply by Duggan Profiles and Steel Service Centre Limited (the “Guarantor”) of its Corrifarm and Profarm products (the “Products”) which are to be used as roofing or cladding in the polluted environment of livestock housing, excluding poultry and pig housing, to the owner or owners of the buildings to which the Products are applied (the “End User”) which are to be used as roofing or cladding in the polluted environment of livestock housing excluding poultry and pig housing. | ||

| 1.2 | Subject to the conditions and limits of this Guarantee, the Guarantor hereby guarantees to the End User the proper performance of the Products for the Term (as hereinafter defined). | ||

2 |

Duration of the Guarantee |

||

| This Guarantee shall enter into effect from the date of sale of the Products and shall not, in any event, exceed the time period of twenty years (the “Term”). | |||

3 |

Scope of Guarantee |

||

| 3.1 | Should the Products be proven to be defective, in full or in part, following a claim to that effect made by the End User, and a subsequent investigation by the Guarantor, to a level whereby the defective Products cover an area greater than 10% or 200m2 (whichever is the lower), of the total external surface of a building to which the Products have been applied, then the Guarantor shall, following consultation with the End User and to the exclusion of responsibility for any other losses or damages, provide such restoration as it sees fit, to the End User. | ||

| 3.2 | It is hereby expressly stated for this Guarantee to be effective, the Products must be installed within 2 months of the date of sale and any defect must be notified to the Guarantor, in writing, within 30 days of discovery. | ||

| 3.3 | The restoration provided by the Guarantor in clause 3.1 above, shall be limited, specifically, to those Products proven to be defective and shall not entitle the End User to any extension or renewal of this Guarantee. | ||

4 |

Limitation of liability |

||

| 4.1 | In the event of the Products being defective, within the Term, the Guarantor’s liability (excluding VAT and transport charges) will be limited as follows: | ||

| 4.1.1 | Less than or equal to 5 years from the date of sale – Liability will be limited to 100% of the sale value of the defective Products excluding VAT. | ||

| 4.1.2 | Greater than 5 years from the date of sale – The liability will be limited to that percentage of the sale value, excluding VAT, calculated as follows (number of full years remaining of the Term, multiplied by 100, divided by the length of the Term less 5). | ||

5 |

Conditions of Corrifarm and Profarm Roofing Product Guarantee |

||

| 5.1 | Buildings, to which the Products are applied, shall be designed and erected according to professional rules and regulations in force together with any recommendations of the Guarantor. | ||

| 5.2 | Buildings, to which the Products are applied, shall be erected and maintained free of mechanical damage and accumulations of debris and other pollutants. | ||

| 5.3 | Storage, installation and use of the Products shall be in accordance with the Guarantor’s recommendations and published best practice at the date of sale. | ||

| 5.4 | Buildings, to which the Products are applied, shall be constructed with adequate ventilation and in accordance with industry best practice and department of agriculture guidelines. | ||

| 5.5 | Appropriate accessories and material shall be used to prevent any acceleration of corrosion of the Products. | ||

| 5.6 | Buildings, to which the Products are applied, should be inspected annually and maintenance undertaken in line with up-to-date best practice literature. | ||

| 5.7 | A natural wash of the organic coated surfaces by atmospheric rainfall shall normally be assured in order to prevent any clogging which can be detrimental to their appearance (dust deposits, etc.). For surfaces which do not receive this natural washing, a regular maintenance shall be done with a minimum frequency as follows: | ||

| 5.7.1 | An annual washing without the use of abrasive or aggressive substances. | ||

| 5.7.2 | A systematic and immediate treatment of any parts which, for various reasons, show signs of corrosion. | ||

6 |

Exclusions from the Guarantee |

||

| This Guarantee shall not cover: | |||

| 6.1 | Corrosion or other defects initiating or resulting from non- protected holes and cut edges. | ||

| 6.2 | Corrosion or other defects initiating or resulting from the collection and/or retention of water and/or other contaminants on or around the Products. | ||

| 6.3 | Corrosion or other defects resulting from above normal concentrations of hydrogen sulphide gas from aerated slurry. | ||

| 6.4 | Products installed on roofs with less than a 10 degree pitch or where water or other contaminants are prevented from running freely from all surfaces. | ||

| 6.5 | Installation of the Products at temperatures other than in the current product data sheet at the time of sale. | ||

| 6.6 | The performance of any touch-up paint or over-paint used on the panels. | ||

| 6.7 | Colour fading of the Products. | ||

| 6.8 | Defects initiating from fire, lightning, flood, explosion, abnormal winds, earthquake, acts of war, riots, civil commotion, radiation, falling objects, vandalism and other extraneous causes, over which the Guarantor has no control. | ||

| 6.9 | Damage caused by misuse, willful act or negligence, by the End User, or any other party. | ||

| 6.10 | Damage to the Products incurred during storage, transport or erection. | ||

| 6.11 | Corrosion or other defects due to accumulations of dirt or debris. | ||

| 6.12 | Corrosion or other defects resulting from inadequate ventilation resulting in severe condensation, or seepage of aggressive or corrosive chemical compounds. | ||

| 6.13 | Any material used in direct contact with or in close proximity to wet and corrosive materials such as wet concrete, wet or treated timber, or other wet material. | ||

| 6.14 | Products exposed to the seafront as defined by a zone where sea water is capable of spraying, either partially or momentarily over the buildings fitted with the Products. | ||

| 6.15 | Any alteration or modification to the Products. | ||

7 |

Assignment |

||

| This Guarantee may not be assigned save with the prior written consent of the Guarantor and the End User. | |||

8 |

Jurisdiction and Applicable Law |

||

| The formation, existence, construction, performance, validity and all aspects whatsoever of this Guarantee will be governed by Irish law and the Irish courts shall have exclusive jurisdiction to settle any disputes which may arise herefrom. | |||

. . . . For Sales Pre 31st December 2018 |

|||

1 |

Objective of the Guarantee |

||

| 1.1 | This guarantee (the “Guarantee”) applies to the sale and supply by Duggan Profiles and Steel Service Centre Limited (the “Guarantor”) of its Corrifarm and Profarm products (the “Products”) which are to be used as roofing or cladding in the polluted environment of livestock housing, excluding poultry and pig housing, to the owner or owners of the buildings to which the Products are applied (the “End User”) which are to be used as roofing or cladding in the polluted environment of livestock housing excluding poultry and pig housing. | ||

| 1.2 | Subject to the conditions and limits of this Guarantee, the Guarantor hereby guarantees to the End User the proper performance of the Products for the Term (as hereinafter defined). | ||

2 |

Duration of the Guarantee |

||

| This Guarantee shall enter into effect from the date of sale of the Products and shall not, in any event, exceed the time period of fifteen years (the “Term”). | |||

3 |

Scope of Guarantee |

||

| 3.1 | Should the Products be proven to be defective, in full or in part, following a claim to that effect made by the End User, and a subsequent investigation by the Guarantor, to a level whereby the defective Products cover an area greater than 10% or 200m2 (whichever is the lower), of the total external surface of a building to which the Products have been applied, then the Guarantor shall, following consultation with the End User and to the exclusion of responsibility for any other losses or damages, provide such restoration as it sees fit, to the End User. | ||

| 3.2 | It is hereby expressly stated for this Guarantee to be effective, the Products must be installed within 2 months of the date of sale and any defect must be notified to the Guarantor, in writing, within 30 days of discovery. | ||

| 3.3 | The restoration provided by the Guarantor in clause 3.1 above, shall be limited, specifically, to those Products proven to be defective and shall not entitle the End User to any extension or renewal of this Guarantee. | ||

4 |

Limitation of liability |

||

| 4.1 | In the event of the Products being defective, within the Term, the Guarantor’s liability (excluding VAT and transport charges) will be limited as follows: | ||

| 4.1.1 | Less than or equal to 5 years from the date of sale – Liability will be limited to 100% of the sale value of the defective Products excluding VAT. | ||

| 4.1.2 | Greater than 5 years from the date of sale – The liability will be limited to that percentage of the sale value, excluding VAT, calculated as follows (number of full years remaining of the Term, multiplied by 100, divided by the length of the Term less 5). | ||

5 |

Conditions of Corrifarm and Profarm Roofing Product Guarantee |

||

| 5.1 | Buildings, to which the Products are applied, shall be designed and erected according to professional rules and regulations in force together with any recommendations of the Guarantor. | ||

| 5.2 | Buildings, to which the Products are applied, shall be erected and maintained free of mechanical damage and accumulations of debris and other pollutants. | ||

| 5.3 | Storage, installation and use of the Products shall be in accordance with the Guarantor’s recommendations and published best practice at the date of sale. | ||

| 5.4 | Buildings, to which the Products are applied, shall be constructed with adequate ventilation and in accordance with industry best practice and department of agriculture guidelines. | ||

| 5.5 | Appropriate accessories and material shall be used to prevent any acceleration of corrosion of the Products. | ||

| 5.6 | Buildings, to which the Products are applied, should be inspected annually and maintenance undertaken in line with up-to-date best practice literature. | ||

| 5.7 | A natural wash of the organic coated surfaces by atmospheric rainfall shall normally be assured in order to prevent any clogging which can be detrimental to their appearance (dust deposits, etc.). For surfaces which do not receive this natural washing, a regular maintenance shall be done with a minimum frequency as follows: | ||

| 5.7.1 | An annual washing without the use of abrasive or aggressive substances. | ||

| 5.7.2 | A systematic and immediate treatment of any parts which, for various reasons, show signs of corrosion. | ||

6 |

Exclusions from the Guarantee |

||

| This Guarantee shall not cover: | |||

| 6.1 | Corrosion or other defects initiating or resulting from non- protected holes and cut edges. | ||

| 6.2 | Corrosion or other defects initiating or resulting from the collection and/or retention of water and/or other contaminants on or around the Products. | ||

| 6.3 | Corrosion or other defects resulting from above normal concentrations of hydrogen sulphide gas from aerated slurry. | ||

| 6.4 | Products installed on roofs with less than a 10 degree pitch or where water or other contaminants are prevented from running freely from all surfaces. | ||

| 6.5 | Installation of the Products at temperatures other than in the current product data sheet at the time of sale. | ||

| 6.6 | The performance of any touch-up paint or over-paint used on the panels. | ||

| 6.7 | Colour fading of the Products. | ||

| 6.8 | Defects initiating from fire, lightning, flood, explosion, abnormal winds, earthquake, acts of war, riots, civil commotion, radiation, falling objects, vandalism and other extraneous causes, over which the Guarantor has no control. | ||

| 6.9 | Damage caused by misuse, willful act or negligence, by the End User, or any other party. | ||

| 6.10 | Damage to the Products incurred during storage, transport or erection. | ||

| 6.11 | Corrosion or other defects due to accumulations of dirt or debris. | ||

| 6.12 | Corrosion or other defects resulting from inadequate ventilation resulting in severe condensation, or seepage of aggressive or corrosive chemical compounds. | ||

| 6.13 | Any material used in direct contact with or in close proximity to wet and corrosive materials such as wet concrete, wet or treated timber, or other wet material. | ||

| 6.14 | Products exposed to the seafront as defined by a zone where sea water is capable of spraying, either partially or momentarily over the buildings fitted with the Products. | ||

| 6.15 | Any alteration or modification to the Products. | ||

7 |

Assignment |

||

| This Guarantee may not be assigned save with the prior written consent of the Guarantor and the End User. | |||

8 |

Jurisdiction and Applicable Law |

||

| The formation, existence, construction, performance, validity and all aspects whatsoever of this Guarantee will be governed by Irish law and the Irish courts shall have exclusive jurisdiction to settle any disputes which may arise herefrom. | |||