Product Overview

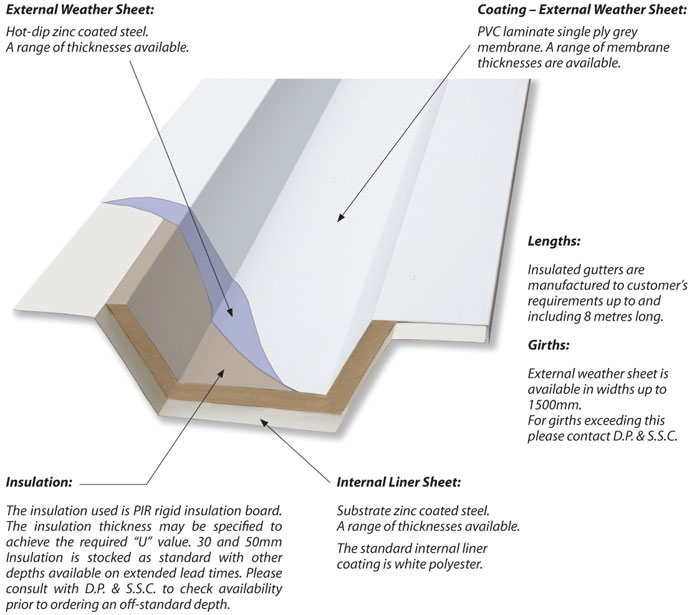

Membrane coated Insulated Gutters are a single component system comprising a PVC membrane lined weather skin with PIR rigid insulation and a steel internal liner sheet. They are made to individual project requirements with options available on both materials specifications and component dimensions.

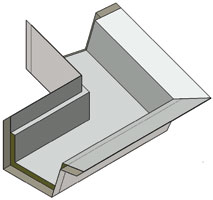

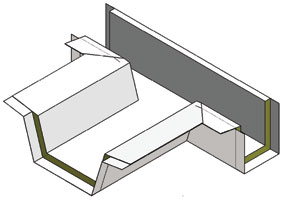

Profile

The gutter cross section is manufactured to project requirements and is limited only by machining and material limitations. The maximum girth is 1500 mm.

Available Lengths

Lengths available to customer requirements up to 8 m.

Insulation

PIR insulation is used as standard.

Insulation Thickness

Common insulation thicknesses are 30 mm and 50 mm but others can be provided on request.

Material

Weather side: 0.8 mm steel with 0.8 mm PVC Membrane

Internal Liner: 0.5 mm steel with 25um White polyester coating

Other material options may be supplied subject to availability.

Gutter Markings

An ID Mark is applied to each gutter during fabrication. These ID Marks can be provided on a site layout drawing available to the customer on request.

Ordering Information

The Duggan Profiles Insulated Gutter Order Form provides an efficient means of ordering. We can also accept details in CAD format.

Packing and delivery

Insulated Gutters are typically bundled in bales of 4-6 units, polythene wrapped and strapped for road transport to site. Care must be taken to avoid damage to units during offloading and handling on site.

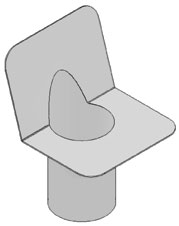

Membrane Coated Insulated Gutter Accessories

Standard 100 and 150mm Outlets are available in membrane type material for heat welding directly to the gutter.

These are supplied loose for fitting on site. The material is that used for the gutter external weather skin. Stop ends are uninsulated as standard but may be supplied insulated on customer request.

These are positioned at the ends of the gutter and are used to assist the discharge of water in the event of inadequate drainage through the normal drainage channels. These are supplied loose for fitting on site. The standard unit is made from the same material as the gutter external weather skin.

Corner units, Tee pieces, Transition pieces, Sumps, Special Outlets etc. are factory made by D.P. & S.S.C. to suit project requirements. Where possible the same material is used for both gutter and fabricated units. In instances where this is not practical components are made from materials compatible with those of the gutter.

Duggan Profiles & S.S.C. Insulated Gutters comprise an external membrane lined weather skin, PIR rigid insulation and an internal liner skin. The specification of each can be configured to suit the individual design requirements. The inside and outside gutter skins are bonded to the insulation and the flanges where the surfaces come together are joined by clinching or riveting. For applications requiring thermal breaks please consult with D.P. & S.S.C.

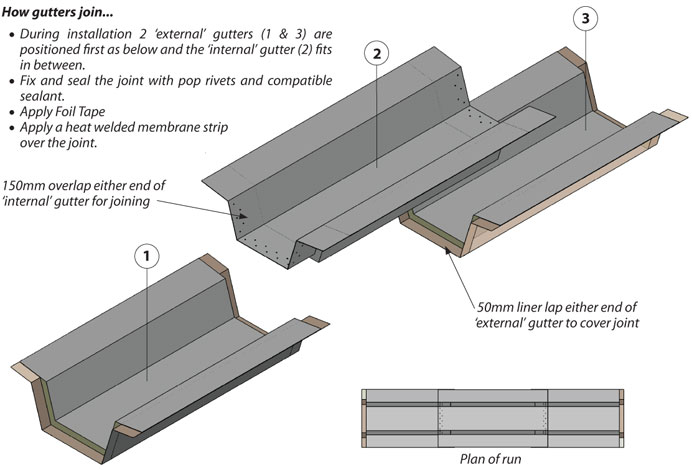

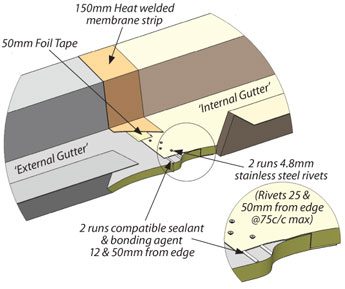

Joints:

Each gutter includes an overlap which forms a lapped joint with the abutting gutter section. Stainless steel rivets, compatible sealant and a heat welded membrane strip secure and seal the joint.

Welding Strip:

1.5mm thick x 150mm wide grey PVC, supplied if ordered, in rolls. The standard joint is made on site by heat welding 50mm to weather sheet of each gutter. Customers should specify if Welding Strip is required when ordering gutters.

Sealants:

Sealants:

D.P. & S.S.C. recommends the use of Soudal Soudaseal 240FC or equivalent.

Fixings:

4.8mm Stainless Steel, length dependant on material thicknesses being fixed and as per manufacturer recommendations.

Supports:

D.P. & S.S.C. Insulated gutters are not structural members and as such require support from the steel frame. Where continuous support is not available off adjacent steelwork Gutter Straps, 50 x 6mm flat bar folded to gutter profile, may be used at 1500mm centres.