General Information:

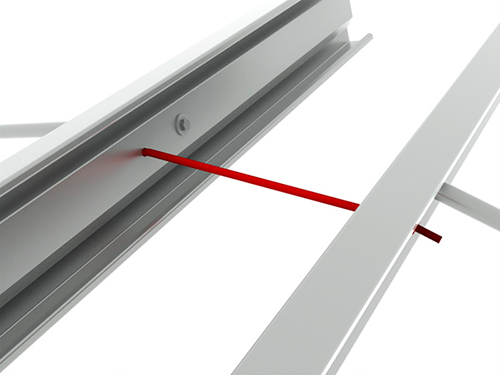

Apex ties are an anti sag component used to reduce the down slope deflection and improve the overall rigidity of the top row of cold-rolled sections in a roof situation. Other anti sag components such as Tube Ties and Threaded Rod Ties are then secured to these rigid members. Apex ties are a bespoke component manufactured from Grade 8.8 M12 zinc plated threaded bar and formed to the length and angle required on site. They connect through 14mm holes in the web of the cold-rolled members on either side of the apex and are secured by nuts and washers. The arrangement is illustrated in the image above as well as the product drawing and CAD file available in the Product code and drawings table below. In situations where there is only 1 slope (mono pitch) the arrangement illustrated will not suffice. In such circumstances the apex member will need to be secured to an appropriate rigid member, most probably the main structure.

Load data:

Apex ties are manufactured from Grade 8.8 M12 threaded bar with the following minimum mechanical properties:

Working limit of Apex Tie: 48.6KN

Ultimate tensile strength: 800 N/mm2

Yield strength: 640 N/mm2

How to order:

In order to manufacture apex ties we require the length and angles as outlined on the product drawing included below. The ends are formed to a length of 60mm and at angles to match the roof slopes. The 60mm dimension is standard in all cases. The relevant product code along with a drawing and CAD file are included in the table below.

ProSigma+ Apex Tie product code and drawings:

|

Code: | Description: | PDF File | |

| DP-APEXTIE | Apex Tie: | |||

| Click on the PDF icon above to download .pdf file. | ||||