The Duggan Profiles range of Eaves Beams comprises 2 section depths in 2mm material and a choice of two distinct material finishes. Users may choose between conventional hot-dip (galvanised) material while an alternative white prepainted steel is available for applications where improved aesthetics or additional anti corrosion protection is desired.

Refer to Material Specification (Galvanised) and Material Specification (Prepainted) for more detailed information.

Eaves Beams from the Duggan Profiles range are roll formed in lengths up to 20m and in angular increments of 1 degree up to 30 degrees.

Eaves Beams may not be produced with angles less than 90 degrees.

Sizes and dimensions

EAVES BEAM SECTION OPTIONS (GALVANISED)

| Product Code | Section Dept (mm) | Thickness (mm) | Angle (Degrees) | Finish |

|---|---|---|---|---|

| DP-EBG180/200/00 | 180 | 2 | 0 – 30 | GALV |

| DP-EBG210/200/00 | 210 | 2 | 0 – 30 | GALV |

EAVES BEAM SECTION OPTIONS (PREPAINTED)

| Product Code | Section Dept (mm) | Thickness (mm) | Angle (Degrees) | Finish |

|---|---|---|---|---|

| DP-PEB180/200/00 | 180 | 2 | 0 – 30 | PREPAINTED |

| DP-PEB210/200/00 | 210 | 2 | 0 – 30 | PREPAINTED |

Note:

The last two digits of the product code denote the angle. All the codes above specify an angle of Zero degrees, to specify an angle greater than Zero the last two digits should be replaced with the required angle. Example: DP-EBG 180/200/06 denotes a Galvanised Eaves Beam of 180 depth with an angle of 6 degrees.

Eaves Beams are available in a range of 2 section depths: 180 or 210mm.

Both depths are available in 2mm steel. The table above lists the available sizes.

Eaves Beams are specified by product code. The codes are defined as per the following examples:

Example 1: DP-EBG180/200/10

DP: Duggan Profiles, used as a prefix for all our sections

EBG: Eaves Beam Galvanised, this defines the profile and distinguishes it from purlins, rails or Cee sections. It also indicates the finish required.

180: The first 3 digits denote the section depth in mm

200: The second block of digits denotes the thickness (2mm).

10: The final block of digits denotes the angle of the Eaves Beam, 10 is 10 degrees, 06 is 6 degrees etc.

Example 2: DP-PEB210/200/20

DP: Duggan Profiles, used as a prefix for all our sections

PEB: Painted Eaves Beam, this defines the profile and distinguishes it from purlins, rails or Cee sections. It also indicates the finish required.

210: The first 3 digits denote the section depth in mm

200: The second block of digits denotes the thickness (2mm).

20: The final block of digits denotes the angle of the Eaves Beam, 20 is 10 degrees.

Typical profile dimensions are indicated, however it should be borne in mind that tolerances associated with the roll forming process means deviation from these nominal indicators is inevitable. The angle may be formed from zero up to 30 degrees in increments of 1 degree.

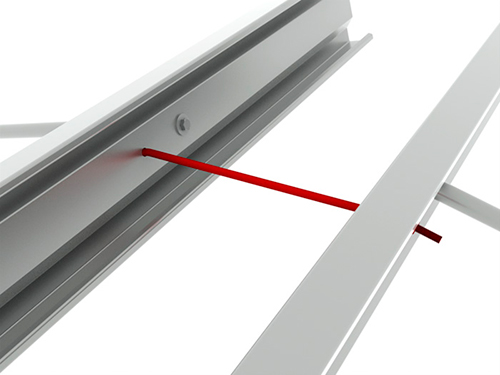

Eaves Beam Punching

Standard gauge lines for cleat and anti-sag holes are 90mm from the top and 60mm on the bottom flange however 14 or 18mm holes may be punched at any position on the section if requested. The standard hole size for cleat connections to the structure is 18mm to suit M16 bolts (Refer to the section on Eaves Beam Cleats for additional information). Holes for the anti sag strut connection are 14mm to accommodate M12 bolts. This is illustrated in the diagram below.

Length

Duggan Profiles can roll form its cold rolled products in lengths up to 20m. Customers should bear in mind the logistics of transportation and site handling before ordering sections of excessive length. If possible cold rolled sections should not exceed 14m for maximum ease of transportation.

Cleats.

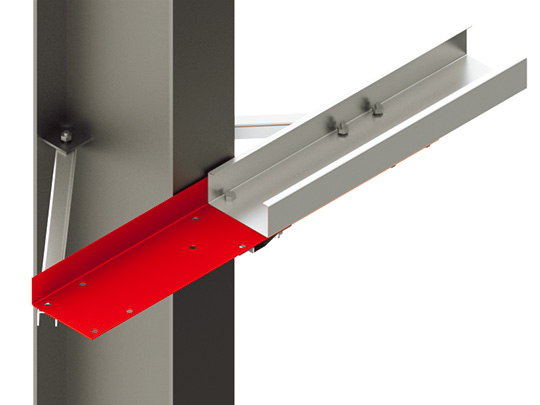

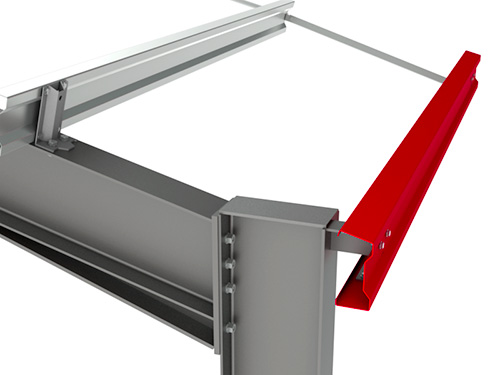

Eaves Beams connect to the supporting steelwork by means of 4 x M16 bolts and a fabricator supplied connection cleat. Duggan Profiles does not provide Eaves Beam Cleats. The standard connection details is shown below.

Material specification (Galvanised)

Eaves Beams from the Duggan Profiles range are manufactured as standard from high proof strength steel for cold forming with the following characteristics to EN 10346:2009

Steel Name HX460LAD

Minimum yield strength (Rel): 460MPa

Corrosion protection: Hot-dip zinc coating

Coating designation: Z275 Coating mass: 275g/m2 (The minimum total coating mass both surfaces using triple spot test)

The material thickness is to EN 10143:2006 Continuously hot-dip coated steel sheet and strip. Tolerances on dimensions and shape

Material specification (Prepainted)

Painted Eaves Beams from the Duggan Profiles range may be manufactured from organically coated structural steel with the following characteristics:

Steel Name S390

Minimum yield strength: 390MPa

Corrosion protection: Hot-dip zinc coating

Coating designation: Z275

Coating mass: 275g/m2 (The minimum total coating mass both surfaces using triple spot test)

The painted finish to EN 10169:2010 is as follows:

Colour: Chalk White*

A 15μm thick flexible primer specially designed to resist corrosion, applied on both sides.

A 20μm thick flexible chemical and corrosion resistant Polyester Resin finish (Chalk White Top Coat) applied on both sides.

*The colour indicated is for information purposes only.

Material samples are the only reliable indicator of colour and are available on request.

The material thickness is to EN 10143:2006 Continuously hot-dip coated steel sheet and strip.

Tolerances on dimensions and shape.

Prosigma+ Eaves Beam Product Drawings

Click on the DXF or PDF icons above to download the CAD (.dxf) or .pdf file.

Trouble downloading?

Right-Click on the DXF icon: this will bring up a menu where you can click on either

‘Save Target As’ or ‘Save Link As’.

Then, after saving the DXF file to your computer you can run your CAD software

and open the DXF file that you saved.

Overview:

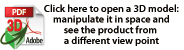

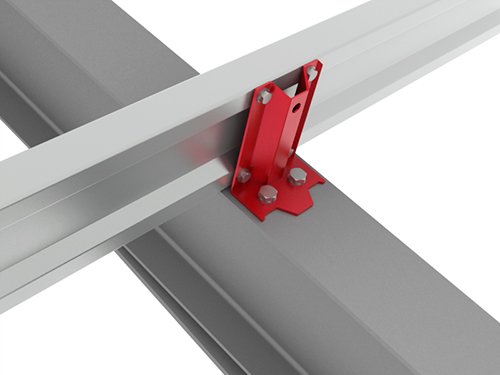

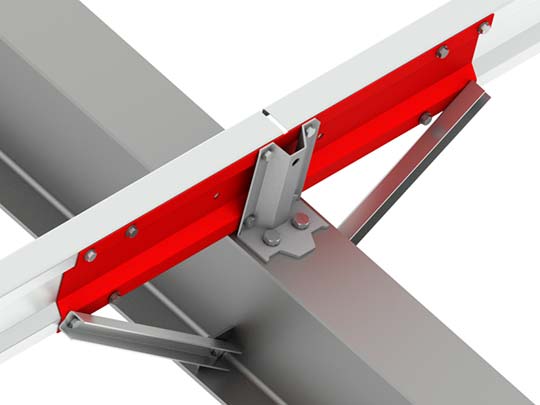

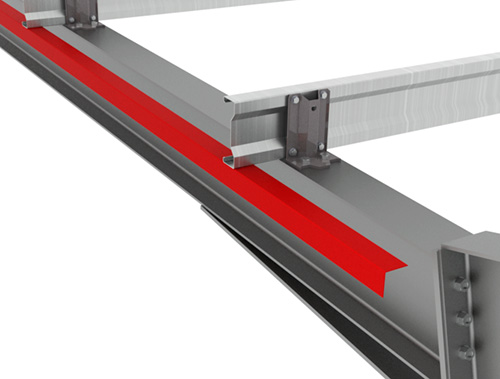

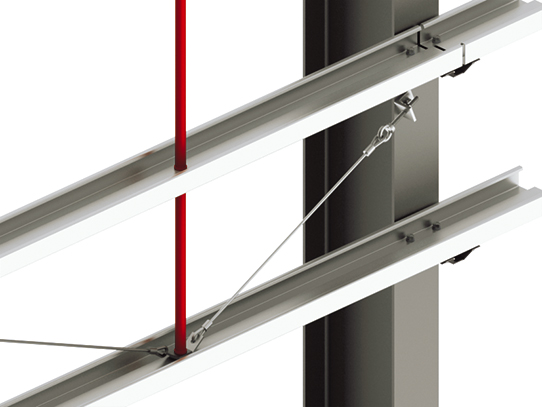

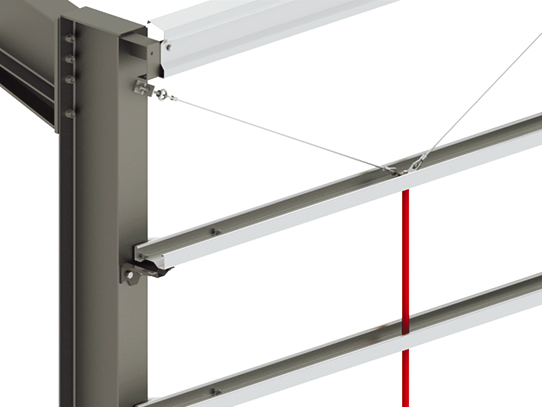

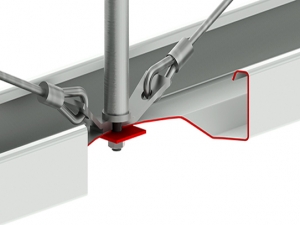

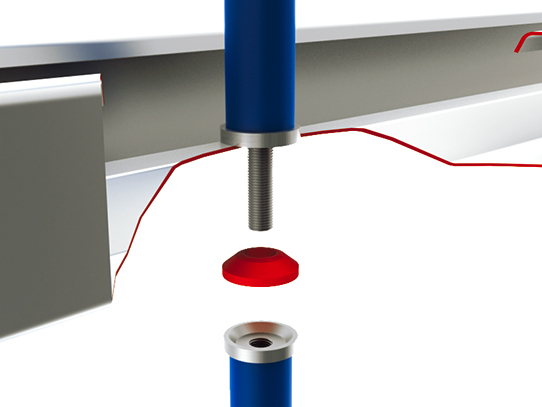

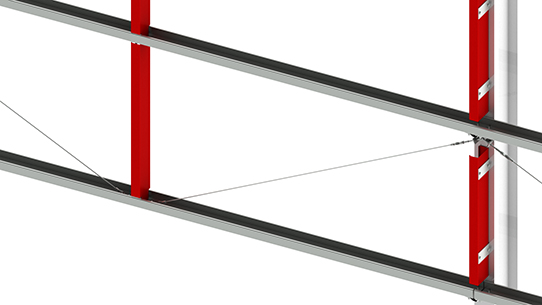

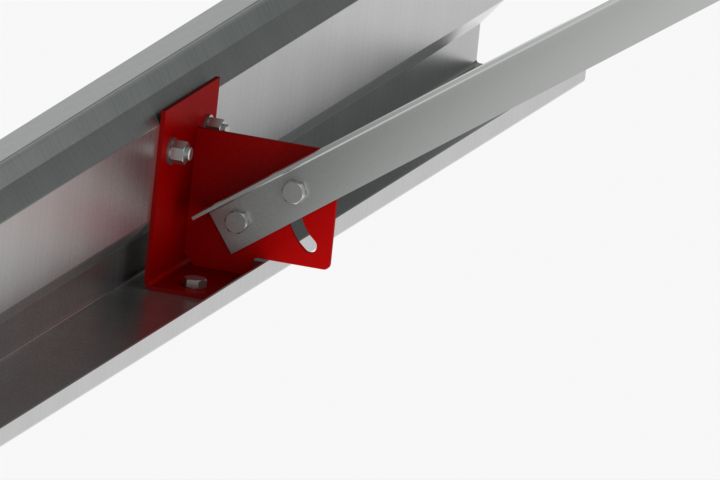

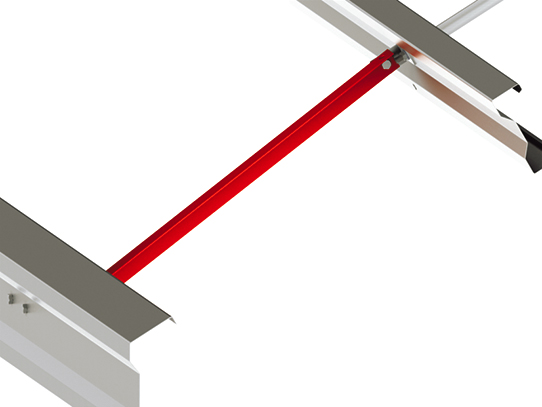

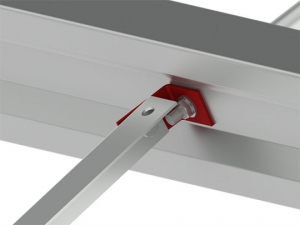

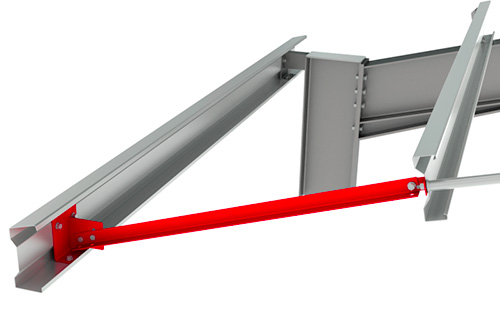

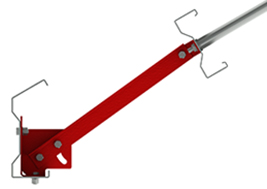

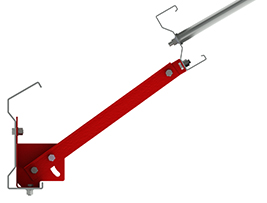

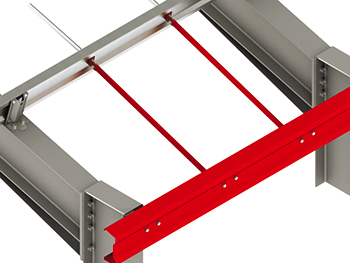

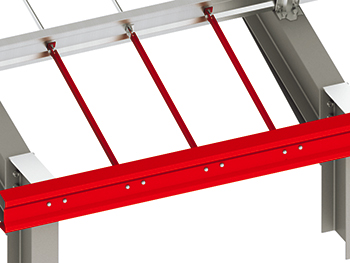

Anti sag support for Eaves Beams is provided by Eaves Struts in conjunction with Eaves Strut Cleats and Eaves Strut to Purlin Cleats and all supported off a rigid structural member such as the cold-rolled sections shown in the images below. Where these are used, connection may be to the bottom flange or the centre web. The preferred option is connection to the web centre as risk of torsion of the cold-rolled member under load is less likely. This option does however require much free space, unobstructed by building members such as tie beams or insulated gutters. Where the path of the Eave Strut is obstructed the alternative arrangement may be considered.

| Eaves support connected to purlin web | Eaves support connected to purlin flange |

|---|---|

|

|

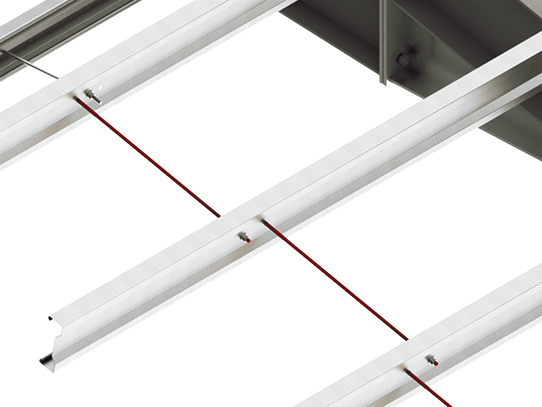

Anti sag support requirements

Anti sag support must be provided for all Eaves Beams. The data shown in the Eaves Beam Load Tables is invalid if this restraint is not included. The requirements are categorised by the distance spanned and are presented underneath.

| Details | Images |

|---|---|

| Span(m): < 6

For spans less than 6m anti sag supports are required at: Mid span |

|

| Span(m): 6 – 10

For spans from 6m up to and including 10m anti sag supports are required at: 1/3 points |

|

| Span(m): < 12

For spans up to 12m anti sag supports are required at: 1/4 points |

|

ProSigma+ Eaves Beam Anti Sag typical details:

| Eaves Beam Anti Sag Connection to Bottom Flange: | |

| Eaves Beam Anti Sag Connection to Web: | |

STRUCAD SUPPORT

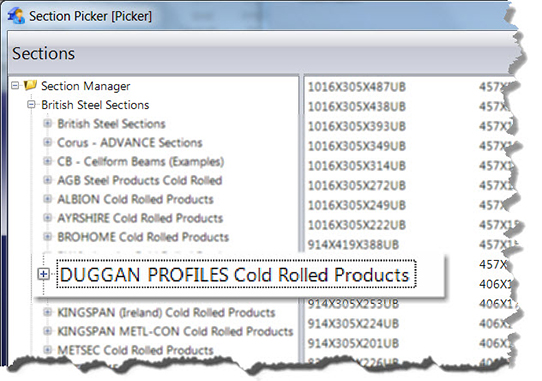

Detailing Support for StruCad Users

The Duggan Prosigma system is fully intgrated in StruCad. The complete range of Duggan Cold rolled sections is available for detailing from the sections catalogue as shown.

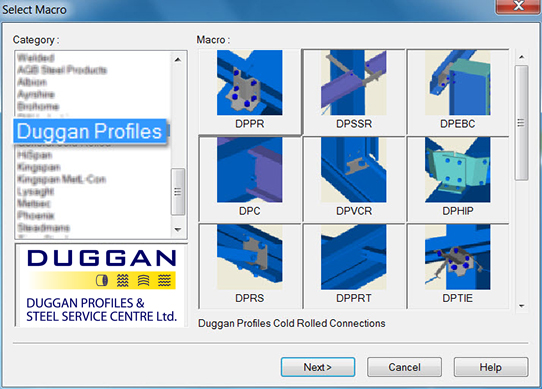

Duggan Connection Macros

In common with the systems of other manufacturers the Duggan Prosigma installation includes a suite of connection macros which may be accessed as shown below.

Purlin/Rail to Column/Rafter

This creates a cleat connection for both the Sigma and Cee sections. The following options are available:

- Prepainted or Galv sections may be used

- The type of Cleat may be defined

- Sleeves may be used

- Rafter Stays may be used

- Firewall slots may be used

- Orientation holes may be added

Simply supported rail to column

This creates a cleat connection for both the Sigma and Cee sections where the members are inset between columns/rafters.

This creates a cleat connection for both the Sigma and Cee sections where the members are inset between columns/rafters.

The following options are available:

- Prepainted or Galv sections may be used

- The type of hot rolled cleat may be defined (Duggan cleats are not suitable)

- Cleats may be slotted

- Members may be Notched around columns

- The inset distance may be varied

Eaves Beam to column

This creates an Eaves Beam cleat connection. The following options are available:

- Prepainted or Galv sections may be used

- Bolt-on or Weld-on cleats may be used

- The stock size may be defined

Note: Duggan Profiles do not supply Eaves Beam Cleats, these must be fabricated as part of the structural steel.

Connections for Cee Sections

This creates a connection between the following:

- Cee‘s and other Cee’s

- Cee’s and Eaves Beams

- Cee’s and columns/rafters

The following options are available:

- Prepainted or Galv sections may be used

- End Flanges may be used instead of cleats

- Hot rolled cleats may be used

- Notching may be used

Note: Use the Vertical Cladding Rail macro for connecting Cee’s to Sigma sections.

Vertical Cladding Rail connection

This creates all connections for the Vertical Cladding Rail (VCR). The following options are available:

- The horizontal rails may be any type of Sigma or Cee

- The VCR must be a Cee

- Cleat connections to columns may be defined

- Cover channels may be defined and used where required

- Tie Ropes may be used

Hip Connection

This creates a cleat connection between a Sigma or Cee and a hip rafter. The following options are available:

This creates a cleat connection between a Sigma or Cee and a hip rafter. The following options are available:

- The purlins may be any type of Sigma or Cee

- Weld-on or Bolt-on cleats may be used

Note: These cleats must be supplied by the fabricator.

Connection for Eaves Struts & Angle Struts

This creates the end connections for the Eaves Strut and the Angle Strut. These are standard connections and no adjustment is required however the following two connection options for the Eaves Strut are available:

- Eaves Strut connected to purlin web

- Eaves Strut connected to purlin flange

Purlin and Rail Tie connection

This creates the connections for Tube Struts, Tube Ties, Threaded Rod Ties and Apex Ties. It also makes provision for the inclusion of Tie Ropes. The following options are available:

- Sigma or Cee sections may be used

- Any Type of Tube Strut may be used

- Ties may be connected end to end or staggered (Anti sag requirements for Curved Roofs require staggered ties)

- Counterformed holes with countersunk bolts may be used

Connection for Tie Rope

This connects Tie Ropes with Tube Struts, Tube Ties, Angle Struts and Vertical Cladding Rails (VCR). The following options are available:

- Sigma or Cee sections may be used as the purlins or rails

- The anchor point at the column/rafter may be adjusted

- The anchor bracket at the column/rafter may be changed

- Tie Ropes can be inset for purlins/rails between rafters/columns

- Counterformed holes with countersunk bolts may be used

Cleader Angle Connection

This calculates the length of Cleader Angle required but does not create a connection. Duggan Profiles supply Cleader Angle in 6m lengths for screw fixing on site.

This calculates the length of Cleader Angle required but does not create a connection. Duggan Profiles supply Cleader Angle in 6m lengths for screw fixing on site.

Service Holes

This creates a Service Hole in Sigma sections 235 and deeper and all Cee sections. There are no user defined parameters for this macro and the hole must be applied on the centreline of the section.

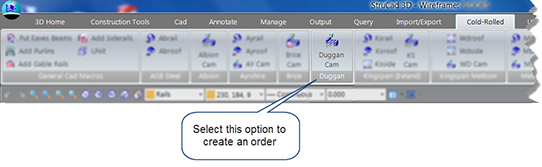

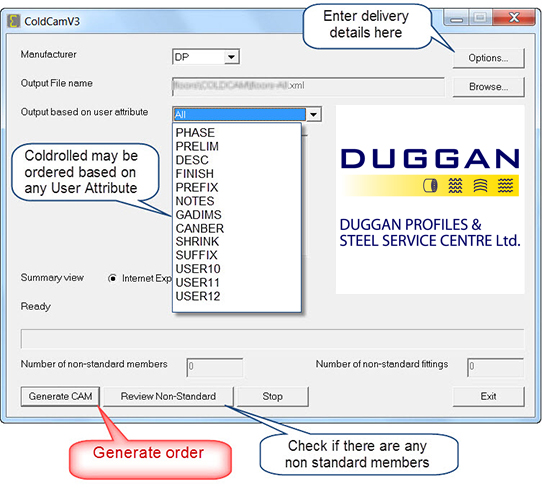

How to create an order:

Cold rolled may be ordered from within the StruCad environment by selecting the “Duggan Cam” option on the cold rolled menu.

The dialog box below appears. The order may include everything in the model or may be broken down by Phase, Finish, Prefix etc., in fact Duggan Cam allows ordering of coldrolled based on any user attribute.

- Choose to order “All” or create the order based on one of the available user attributes.

- Check if there are any non standard items. Items may appear non standard for various reasons such holes not on expected gauge lines or items too long to make. If an item cannot be manufactured it must be edited before ordering. Drawings of non standard items should be included with the order.

- Enter delivery details.

- Click “Generate CAM”.

- Two files are created and saved to the folder you selected (Model directory/COLDCAM/ by default). These two files are “modelname”.asp and “modelname”.xml and they contain the list of non standard items and the order details respectively. Attach these 2 files to an email along with drawings of any non standard items and send them to your normal sales contact. Your order is now placed.

ProSigma+ Eaves Beam HX460LAD (Galv.) 180mm – Load Tables

ProSigma+ Eaves Beam HX460LAD (Galv.) 210mm – Load Tables

ProSigma+ Eaves Beam S390 (Prepainted) 180mm – Load Tables

ProSigma+ Eaves Beam S390 (Prepainted) 210mm – Load Tables

‘SCI Assessed Quality Mark’. This mark testifies that the Steel Construction Institute (SCI) has independently verified the technical data above.

‘SCI Assessed Quality Mark’. This mark testifies that the Steel Construction Institute (SCI) has independently verified the technical data above.

Figures and Comments given here are given for guidance purposes only. While care has been taken to ensure accuracy Duggan Profiles & Steel Service Centre Ltd. and its related companies do not accept liability for errors / or omissions. Customers should satisfy themselves of the suitability of the products supplied or manufactured by Duggan Profiles & Steel Service Centre Ltd. for the use intended.